- Home Page

- Company Profile

-

Our Products

- Power Plant Spares

- RO-DM Plant Spares

- Raw Materials Handling spares

- Industrial Sprocket

- Electric Transfer Car Trolley

- VIV Damper

- Jaw Plate

- Rotary Lump Breaker

- Hammer

- Conveyor Pulley & Idlers

- Stirrer Agitator

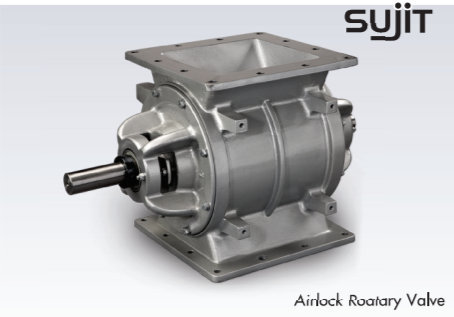

- Airlock Rotary Valve

- CI Filter Plate

- Industrial Hopper

- Mining Screen

- SS Tank

- Conveyor Roller

- MS SS Sandwich Hopper

- Conveyor System

- Screw Conveyor

- Skip Hoist Bucket

- Vibrating Conveyors

- Anchor handling

- Stacker Reclaimer Bucket

- Hammer Crusher Arm

- Conveyor Roller Chain Sprocket

- Conveyor Chain

- Crusher Rotor For Impactor

- Rotary Valve

- Contact Us

Skip Hoist Bucket

Product Details:

- Product Type Skip Hoist Bucket

- Material Mild Steel

- Surface Paint Coated

- Application Construction Material Handling

- Dimension (L*W*H) 1200 mm x 900 mm x 850 mm

- Weight 140 Kg

- Color Grey

- Click to view more

X

Skip Hoist Bucket Price And Quantity

- 05 Piece

- Top Loading

- Concrete, Sand, Gravel

- Bottom Discharge

- Up to 30 Meters

- Standard Export Packaging

- Manual / Motorized

- Reinforced Steel Frame

- Heavy Duty Pulley System

- 500 Litres

- Available

Skip Hoist Bucket Product Specifications

- 140 Kg

- Construction Material Handling

- 1200 mm x 900 mm x 850 mm

- Skip Hoist Bucket

- Grey

- Paint Coated

- Mild Steel

- Top Loading

- Concrete, Sand, Gravel

- Bottom Discharge

- Up to 30 Meters

- Standard Export Packaging

- Manual / Motorized

- Reinforced Steel Frame

- Heavy Duty Pulley System

- 500 Litres

- Available

Skip Hoist Bucket Trade Information

- Per Day

- 1 Months

Product Description

We are famous for manufacturing and supplying quality checked Skip Hoist Bucket. With the aid of cutting edge tools and techniques, this bucket is manufactured using premium grade components by our deft professionals at our premises. Our valuable clients can buy this bucket from us at cost effective rates. For crushing the size of materials, the provided Skip Hoist Bucket is highly demanded in steel, foundry, construction industry and waste management plants.

Features:

- Hassle free performance

- Less maintenance

- Power efficient

- High durability

Heavy-Duty Construction for Reliability

Built with a reinforced steel frame and premium mild steel, this skip hoist bucket is engineered to withstand demanding site conditions. Its robust structure and 140 kg weight offer steady and secure operation, vital for frequent use on large construction sites. The paint-coated surface further increases longevity by resisting corrosion.

Flexible Operation and Customization

This bucket is available in manual and motorized configurations to suit different operational preferences. Additionally, customization options allow adjustments to specifications such as capacity or operating mechanism, ensuring a perfect fit for specific job site requirements.

Efficient Material Handling for Various Applications

Ideal for transporting concrete, sand, or gravel, this skip hoist bucket streamlines vertical material movement up to 30 meters. The top loading and bottom discharge design enhance workflow efficiency, facilitating smoother operations for construction projects, especially in high-rise structures.

FAQs of Skip Hoist Bucket:

Q: How is the skip hoist bucket loaded and discharged?

A: The skip hoist bucket features a top-loading design, allowing materials such as concrete, sand, or gravel to be easily loaded. Discharge is accomplished through a bottom outlet, which facilitates quick and precise unloading at the required location.Q: What is the process for lifting materials with this bucket?

A: Materials are loaded into the bucket, after which the heavy-duty pulley systemoperated manually or by motorlifts the bucket to heights up to 30 meters. Upon reaching the desired elevation, the operator activates the bottom discharge system to release the contents safely.Q: Where is this skip hoist bucket typically used?

A: This bucket is well-suited for construction sites, especially for handling material transfers in multi-storey building projects. It efficiently transports aggregates and mixtures like concrete to elevated levels.Q: What are the key benefits of using this skip hoist bucket on construction sites?

A: Its robust structure and efficient loading/discharge mechanism save time and reduce manual labor. The buckets flexibilityoffering both manual and motorized optionsensures adaptability for various project scales and site conditions.Q: Can the bucket be customized to meet specific project requirements?

A: Yes, customization is available for capacity, operating mechanism, or other specifications to align with distinct job site needs. Clients can discuss their requirements to receive a tailored solution.Q: When should a motorized operating type be considered over manual?

A: Motorized operation is ideal for high-frequency use, heavy loads, or when faster lift cycles are required. Manual operation suits smaller jobs or sites with limited access to power.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email