- Home Page

- Company Profile

-

Our Products

- Power Plant Spares

- RO-DM Plant Spares

- Raw Materials Handling spares

- Industrial Sprocket

- Electric Transfer Car Trolley

- VIV Damper

- Jaw Plate

- Rotary Lump Breaker

- Hammer

- Conveyor Pulley & Idlers

- Stirrer Agitator

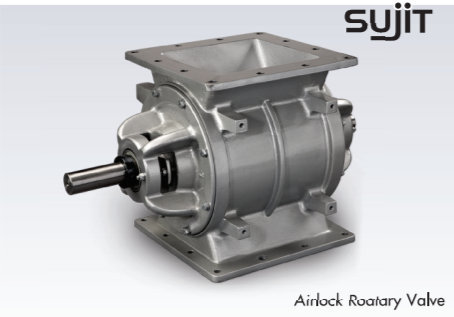

- Airlock Rotary Valve

- CI Filter Plate

- Industrial Hopper

- Mining Screen

- SS Tank

- Conveyor Roller

- MS SS Sandwich Hopper

- Conveyor System

- Screw Conveyor

- Skip Hoist Bucket

- Vibrating Conveyors

- Anchor handling

- Stacker Reclaimer Bucket

- Hammer Crusher Arm

- Conveyor Roller Chain Sprocket

- Conveyor Chain

- Crusher Rotor For Impactor

- Rotary Valve

- Contact Us

Rotary Lump Breaker

Product Details:

- Product Type Rotary Lump Breaker

- Material Stainless Steel

- Surface Polished Finish

- Application Crushing or breaking lumps in bulk material handling systems

- Dimension (L*W*H) 1150 mm x 650 mm x 500 mm

- Weight Approx. 210 kg

- Color Silver

- Click to view more

X

Rotary Lump Breaker Price And Quantity

- 05 Piece

- <72 dB

- Hardened Stainless Steel

- Gearbox Driven

- 415 V

- 500 to 5000 kg/hr

- Heavy-duty, twin-shaft design

- Up to 100 mm

- 5 HP

- 8 mm to 40 mm (adjustable)

- Three Phase

- Floor Mounted, Flanged Base

- Overload Protection, Safety Guards

Rotary Lump Breaker Product Specifications

- Approx. 210 kg

- Polished Finish

- Rotary Lump Breaker

- Silver

- Crushing or breaking lumps in bulk material handling systems

- Stainless Steel

- 1150 mm x 650 mm x 500 mm

- <72 dB

- Hardened Stainless Steel

- Gearbox Driven

- 415 V

- 500 to 5000 kg/hr

- Heavy-duty, twin-shaft design

- Up to 100 mm

- 5 HP

- 8 mm to 40 mm (adjustable)

- Three Phase

- Floor Mounted, Flanged Base

- Overload Protection, Safety Guards

Rotary Lump Breaker Trade Information

- Per Day

- 1 Months

Product Description

Supported by a team of adroit professionals, we offer a broad collection of Rotary Lump Breaker. The provided breaker is extensively used in pharmaceutical, construction, food and beverage, chemical and fertilizer industries for reducing the size of large size materials into granules. Our offered beaker is accessible from us at market leading rates. With the aid of cutting edge tools and techniques, this Rotary Lump Breaker is manufactured using premium quality components at our manufacturing unit.

Features:

- Dimensionally accurate

- Easy to install

- Simple maintenance

- Highly durable

Robust Design for Demanding Applications

This rotary lump breaker is crafted with a heavy-duty, twin-shaft rotor and features hardened stainless steel blades, ensuring long-lasting performance even under continuous, intensive use. Its floor-mounted, flanged base is designed for stability and reliability, supporting industrial operations with high volume requirements.

Versatile Size Reduction for Bulk Materials

Capable of processing feed sizes up to 100 mm and producing adjustable discharge sizes from 8 mm to 40 mm, this machine efficiently manages a wide spectrum of material types. The gearbox-driven system delivers smooth, consistent results, making it an asset for any bulk material handling setup.

Safety and Maintenance Made Simple

With built-in overload protection and comprehensive safety guards, the rotary lump breaker ensures the wellbeing of operators. Additionally, its polished stainless steel construction resists corrosion and is easy to clean, aiding in hygienic processing environments.

FAQs of Rotary Lump Breaker:

Q: How does the rotary lump breaker operate in bulk material handling systems?

A: The rotary lump breaker operates by utilizing its heavy-duty, twin-shaft rotor equipped with hardened stainless steel blades to crush or break larger lumps of material. The crusher handles feed up to 100 mm and breaks it down to the desired discharge size, which can be adjusted between 8 mm and 40 mm. This mechanism ensures smooth downstream processing in bulk material handling systems.Q: What are the primary benefits of using this rotary lump breaker?

A: The primary benefits include efficient size reduction of bulk materials, adjustable discharge sizing, robust stainless steel construction, and quiet operation. Its advanced safety features, such as overload protection and safety guards, promote safe working conditions, while the polished surface simplifies cleaning and maintenance.Q: When should this machine be integrated into a production line?

A: The rotary lump breaker should be integrated whenever bulk materials tend to form clumps during storage or transport, disrupting continuous flow in processing systems. It is especially useful prior to conveying, mixing, or feeding applications to maintain consistent material size and improve overall production efficiency.Q: Where can this rotary lump breaker be installed?

A: This equipment is designed for floor mounting with a flanged base, allowing for stable and secure installation in diverse industrial settings. Its compact design (1150 x 650 x 500 mm) facilitates integration into new or existing bulk material handling systems, commonly deployed in manufacturing, chemical, pharmaceutical, and food industries.Q: What safety features are included to protect operators during use?

A: Safety is prioritized through integrated overload protection, which prevents motor damage during operation, and protective safety guards that shield operators from the moving parts. These measures help minimize risk and ensure a safe working environment during continuous industrial use.Q: How can the discharge size be adjusted to suit specific processing requirements?

A: The discharge size of the rotary lump breaker can be easily set between 8 mm and 40 mm, allowing operators to tailor the output for various downstream processes. Adjustment is typically performed through accessible controls or settings, ensuring flexibility and control over final product particle size.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email